UV Disinfection System Without Mercury

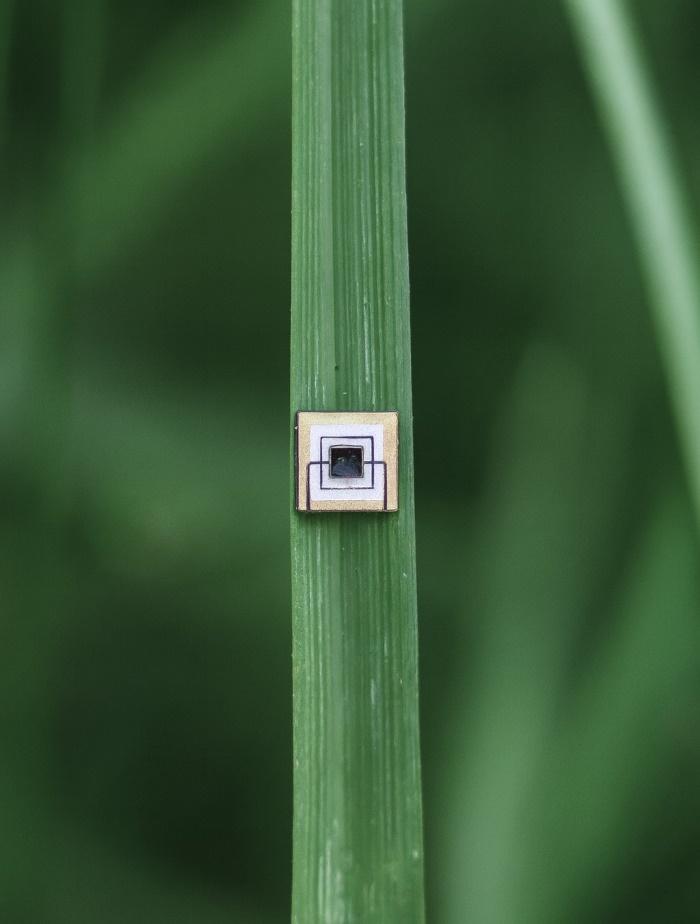

UV-C LED systems provide full-scale water disinfection without any mercury. Unlike traditional mercury-vapour UV lamps, LED reactors use solid-state light sources, meaning there is no risk of glass lamp breakage, no hazardous material handling, and no mercury exposure to staff, equipment or treated water.

UV-C LED systems are currently the only ultraviolet disinfection technology that operates entirely without elemental mercury.

Benefits of mercury-free UV disinfection systems

Mercury-free UV-C LED systems:

- do not contain elemental mercury

- eliminate the risk of lamp breakage and water contamination

- avoid hazardous-waste handling and disposal requirements

- naturally align with Minamata Convention objectives

- offer safer, longer-lasting and more robust solid-state operation

Why traditional UV systems contain mercury

Conventional UV disinfection lamps use elemental mercury to produce germicidal ultraviolet light, typically containing 5–200 mg depending on the lamp type. As glass tubes operating under pressure, they are vulnerable to damage during transport, installation and routine maintenance, and must be managed as hazardous waste throughout their life cycle.

During operation, the mercury inside the lamp vaporises, forming the plasma that emits UV light. If the lamp or its quartz sleeve fractures, this vapour or mercury-bearing particulate can enter the water stream or escape into the surrounding environment, creating an immediate contamination event. Breakage during handling is the most frequent cause of exposure, while improper disposal poses additional risks to operators and local ecosystems.

Why Mercury-Free Matters in Water Treatment

- Mercury UV lamps are positioned in or adjacent to the water stream.

- If a lamp breaks, contamination is immediate and difficult to remediate.

- UV-C LED systems eliminate this risk entirely because no mercury is present at any stage of the disinfection process.